High Throughput & High Output Polyolefin Synthesis, Screening, Optimization & QC

- Home

- Automated Solutions

- High Throughput & High Output Polyolefin Synthesis, Screening, Optimization & QC

High Throughput & High Output Polyolefin Synthesis, Screening, Optimization & QC

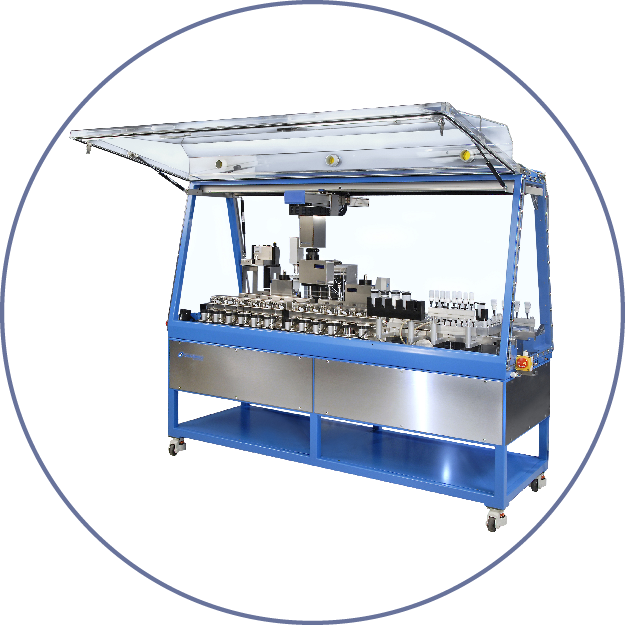

Chemspeed’s SMOLEFIN technology is the premier solution for high throughput and high output catalyst research and development, opening new dimensions to synthesize, reformat, store and apply the most sensitive and aggressive catalysts and reagents.

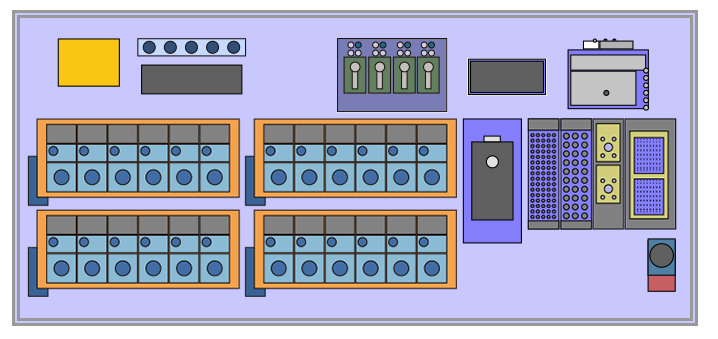

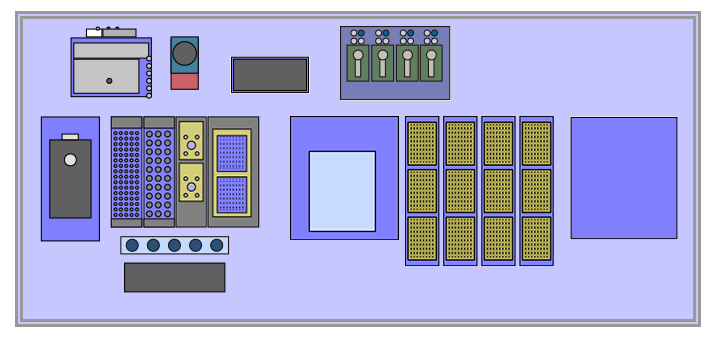

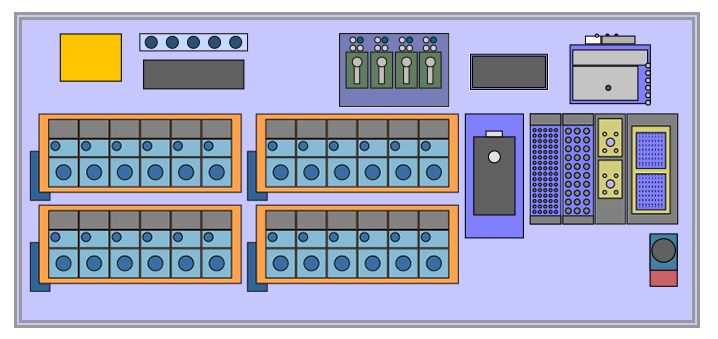

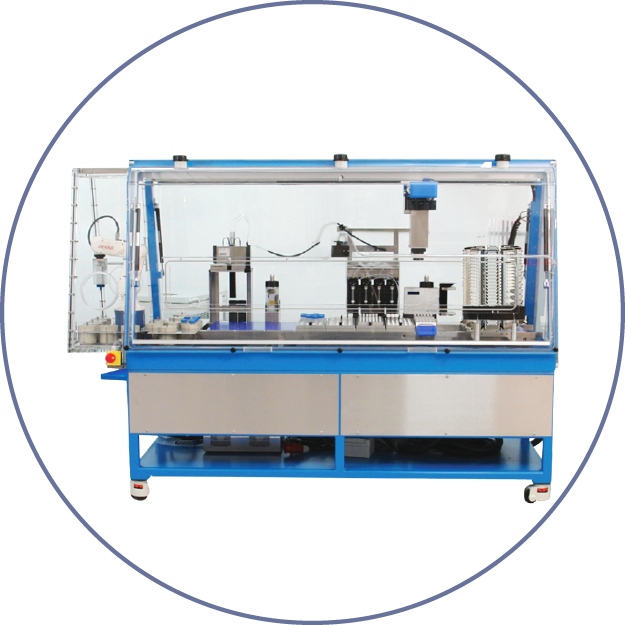

The autoplant POSYCAT platform facilitates catalyst synthesis in up to 36 individually controlled and monitored process reactors. Difficult tasks such as accurate dispensing of solids / liquids; and pH adjustment can be easily performed throughout the reaction. Advanced robotics also enables tedious product purification steps such as filtration, centrifugation, and vacuum drying to be done with ease.

.png)

SWING

SWING

AutoPlant PosyCat

SWING Smolefin

SWING Smolefin

4 Needle-Head

4 Needle-Head

Volumetric Liquid

Transfer Unit Solid

Solid

Dispensing Unit GDU-P

GDU-P

(Gravimetric Dispensing

Unit – Powder) Diluter Syringe

Diluter Syringe Formulation Vessels

Formulation Vessels

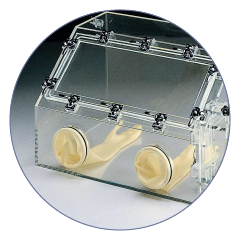

Glovebox

Glovebox

Chemspeed

Chemspeed

AutoSuite Interface Chemspeed

Chemspeed

VLab

Conclusion

Chemspeed’s SMOLEFIN technology provides a true step-change in catalyst reformatting, sealing, storage and application. The SMOLEFIN concept, together with advanced reactor and robotic technology, addresses all technical challenges of handling sensitive catalysts and reagents.

The SMOLEFIN technology sets up a standardized catalyst library for polyolefin catalyst development and opens up possibilities beyond traditional synthetic and quality control approaches. Whether synthesizing homogeneous or heterogeneous catalysts, SMOLEFIN offers an innovative solution with exceptional flexibility and productivity, taking polyolefin catalyst R&D to the next level.